Plastic Moulding Techniques

The plastic is synthetically produced non-metallic compounds. Plastic can mould into various forms and hardened for commercial use. The plastic products are easily seen. The plastic products we use like jars, protective caps, bottles, toys, kitchen utensils, accessories and many more.

We cannot imagine the world without plastic products. The keyboard and mouse we use is also made with plastic moulding. The plastic part of chairs which you sit is also made with the same process.

The process is just simple. The molten liquid plastic is inserted into a mould like the plastic bottle. After that, it is left for cooling and after that the final product is ready.

The moulds are used to form various plastic products like cabinets, barriers, barricades, traffic signage, garden pots and many more.

If you want to start a plastic moulding process, you should have to understand the different processes first. Choose one of the plastic moulding processes according to your budget, resources and expertise. Below there are various processes for plastic moulding.

Blow Moulding

In the blow moulding process, the air pressure is used to inflate the molten plastic into the mould cavity. This process is used to make one-piece hollow plastic products like bottles and containers. The blow moulded items are widely used in consumer beverages and manufacturers arrange the production for maximum numbers.

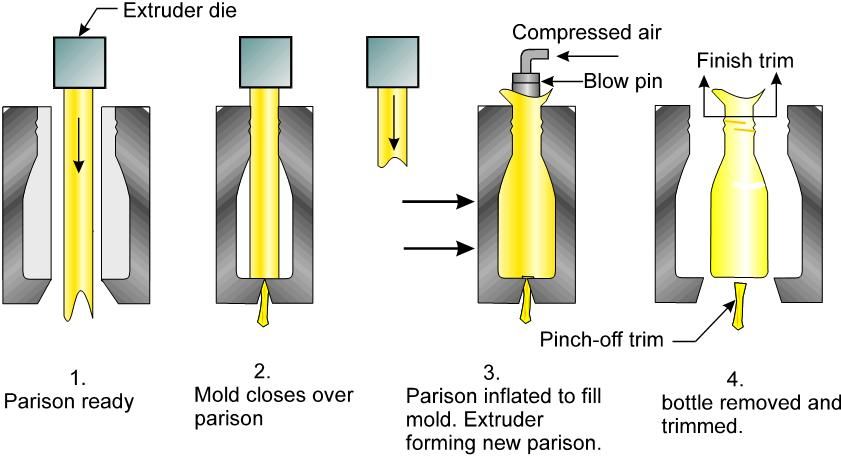

The blow molding process has two steps:

– Starting the process with making the tube of molten plastic called parison.

– Inflate the parison into the final shape.

The Parison is formed from extrusion or injection moulding techniques.

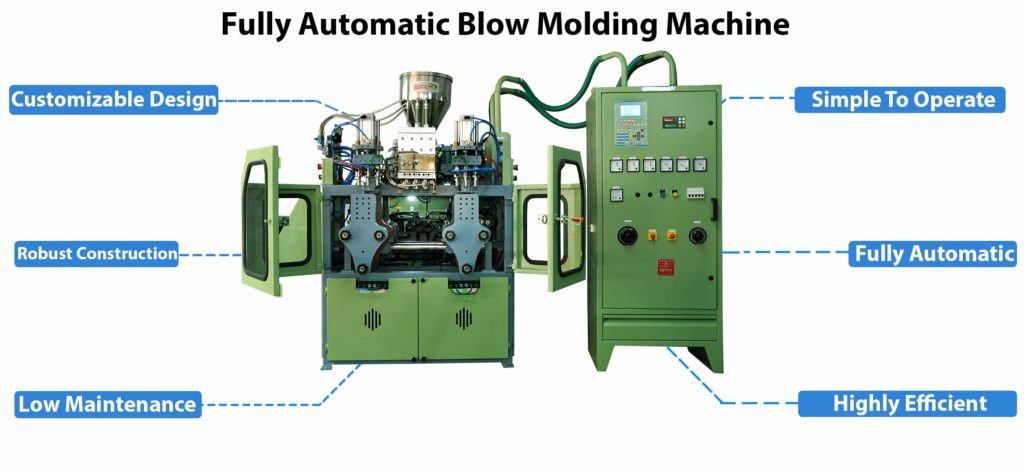

Extrusion Blow Moulding

Manufacturers used extrusion blow moulding for high-production operations for making plastics bottles. The process is automatic and combines with operations like bottle filling and labeling. The blown containers must be rigid. The rigidity depends on various factors like wall thickness.

The extrusion blow moulding process contains below steps.

– Extrude the Parison.

– Cut the Parison from the top and seal at the bottom and the two halves of mould come together.

– After inflating the plastic tube took the mold cavity’s shape.

– Open the mold and remove the final product.

Injection Moulding

The injection blow molding process contains the injection of mold the prison instead of extrusion. It has low production rate than the extrusion process.

The process has below steps.

– Injection-mould the parison around a blowing rod.

– The parison is transferred to a blow mold.

– Inflate the soft polymer to the mold.

– Open the mould and remove the product.

Stretch Blow Moulding

The manufacturers use the variations of injection blow moulding known as stretch blow moulding. In this technique, the blowing rod is extending downward into the injection moulded parison and this stretch the plastic and create a more stressing of polymer than conventional injection blow moulding. The final product is more rigid, higher transparency and it is more impact-resistant.

The Polyethylene terephthalate (PET) is the most widely used material for plastic injection moulding. The PET is polyester with low permeability and the stretch-blow-molding process gives strength and it is ideal for making containers for carbonated beverages.

The Stretch blow moulding steps:

– Injection moulding

– Stretching

– Blowing

Blow Moulding Materials and Products

The polyethylene (PE) is an ideal for blow moulding process as it has high density and high molecular weight polyethylene.

Materials used for blow moulding:

– Polypropylene

– Polyvinylchloride (PVC)

– Polyethylene terephthalate

Rotational Moulding

Rotational moulding or roto moulding use gravity inside a rotation mold to create a hollow form. This technique is used also as an alternative to blow moulding to make the large, hollow shape. This is used for thermoplastic polymers but now thermoset and elastomer are more common. The roto moulding is better than blow moulding for more complex external geometries, large parts and for lower production quantities.

The roto moulding process has below steps.

– First, load a predetermined amount of polymer powder into a split mould cavity.

– Heating and rotating the mould on two perpendicular axes so the powder can coat the mould’s internal surfaces equally and make sure to make uniform thickness layer.

– Open the mould and unload the ready product.

The speed during the process is slow. The process is done with gravity not with centrifugal force and this coat the mould surfaces.

The Rotomolding Moulds

The rotomoulding process is simple and less expensive than injection moulding and blow moulding. But the production cycle took more time around 10 minutes. To minimize time there is three station moulding machine.

First Station – In this station, unloading of final product and load the powder for the next step in the cavity.

Second Station – the Heating station where hot-air convection heats the mould as rotate and the temperature inside reaches up to 375o C depends on polymer and item molded.

Third Station – The third station is a cooling station that cools the mould with cold air or spray of water to solidify the plastic moulding inside.

The products are made with rotational moulding.

Toys, Boat and canoe hulls, Sandboxes, small swimming pools, Buoys and other floatation items, truck body parts, automotive dashboard, fuel tanks. Furniture, garbage cans, fashion mannequins, containers, storage tanks and many more.

The material used for roto moulding

– Polyethylene, mainly HDPE

– Polypropylene

– Acrylonitrile butadiene styrene (ABS)

– High-impact polystyrene

The plastic moulding process is a technical process which cannot be done by everyone. It requires knowledge about various materials and knows the process in every stage.

So it is advisable to study the business and market of your final product.