How to Clean Head of an Extrusion Blow Molding Machine?

For making products made from high-density polyethylene (HDPE), polypropylene (PP), polyethylene terephthalate (PET) and polyvinyl chloride (PVC) thee extrusion blow molding machines are used. With these materials, you can make a wide range of products like plastic bottles, fuel tanks, toys, and many more.

In the process, the extrusion blow molding machine molten resin extrudes into a parison from cylindrical shape. The two halves of the mold close around it. At both the top and bottom portion of the mold, the cylindrical shape of the mold pinches tight when the tube is in the center.

In the mold, the pressurized air through a needle and is inserted in the tube and this expansion to the mold shape. After cooling down the resin, it becomes solid and mold is open and after finishing the product is ready. A manufacturer can add colorants, adhesive or barrier layers with the resin.

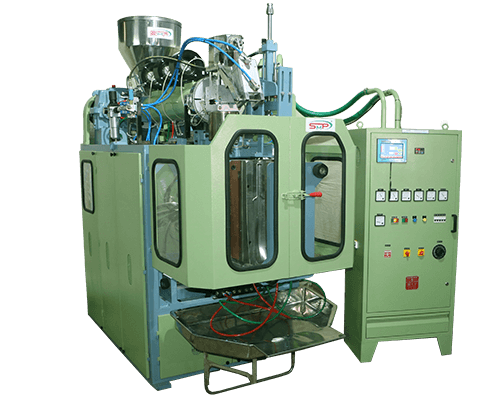

SMP is a trusted extrusion blow molding machine manufacturer in India that provides excellent quality machines. There are slight differences in the blow molding machine design and it depends on extrusion blow molding machines.

These are

Material Hopper

Extruder

Hydraulic Cylinder

Accumulator head

Blow pin

Closing clamp

Blow Mold

Mold platen and clamping unit

For the operations of the machine, all the parts must in perfect condition. The head of an extrusion blow molding machine is very important.

How to Clean the Head?

First, for the cleaning process of heads of extrusion blow molding machine, disconnect or shut off the auxiliary feeding equipment. For better production and precision product the parison head must be clean.

Some polymers degrade during the molding process when it runs at high temperatures. Now if the head is not clean regularly this degraded material accumulates in the head. And if this happens it creates stripes on the surface and the product doesn’t look good aesthetically.

Now before removing the head from the machine use the electric heater to increase the temperature up to require the temperature to melt the plastic. After that remove and open the head and with the copper-beryllium or copper for collecting the melted resin. With the high-pressure air combined with brass cotton for eliminating the remaining material. Also, for removing melted plastic, the anti-sticking agent can be used.

After completion of cleanup, you can start the extrusion blow moulding machine. In the cleaning process try to clean maximum contamination. If this takes more time, you can install a new screen pack and make adjustments to clean the head.