Factors that Affect the Price of a Blow Moulded Part

The manufacturers want to make the best quality product that suits the customer’s pocket. There are various aspects that need to be considered to cut down the production cost of the blow-moulded part.

Today we discuss five common aspects which affect the price of the blow-moulded part.

1. Resin Type

The material used in the product has an important impact on the cost. The High- and low-density polyethene is known as LDPE and HDPE, polypropylene, or PP are widely used resins as they are less expensive.

There is also the price difference between materials, virgin resins are depending on the price of crude oil or natural gas. The prices fluctuate with time.

2. Dimension of the Part

Generally, the bigger the part has more price. But there are ways to cut down the price of the bigger part. For instance, using the resin which maintains its strength even blown very thin. This can minimize the requirement of resin need for larger products. Also, adjusting the blow conditions and part in the mold and machine can save the maximum cost.

3. Structural Requirements

The corners, tabs, handles, compartments, and other structural requirements also impact the price of blow moulding project. Each of the special features of the part needs to be unique tooling and also affect the amount of resin required. The computerized finite element analysis helps to determine the area which may fail. These can be overcome by design and material programming before production.

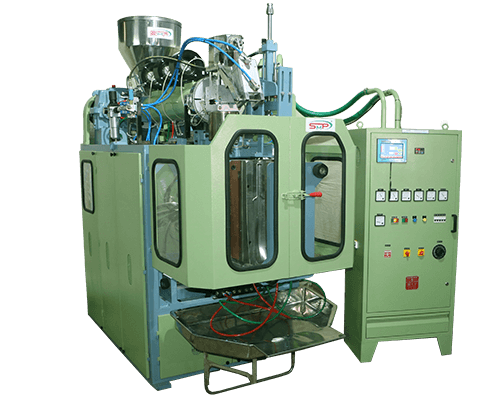

4. Tooling

The tooling cost is the main part of the capital expenditure of the blow moulding project to run. This includes the customized mould and other machinery used to produce a specific part. The tooling includes the part’s structural requirements, size, and resin type. With the blow moulding, there is more creative design can produce. The moulds are typically made from aluminium which has 5 times higher thermal conductivity than the P-20 steel and has 50 to 70% faster cycles.

5. Quantity

The number of products manufactured in shingle time has an impact on the part costs. It is beneficial to produce a large number of products to eliminate initial set-up costs and allows continuous improvements. The higher the quantity the less the price of the part.