We all know that toys are an integral part of our childhood. Toys not only entertain kids but also help them develop their imagination and dexterity.

No other thing can take the place of toys in childhood and that’s the reason why the toy business has been running for years and will continue in the future also. And this business will also support the Indian government.

If you are thinking of starting a toy business, then your decision is right and you can earn good profits from this business.

So today I will tell you how you can start a toy manufacturing business in India by following these 5 steps.

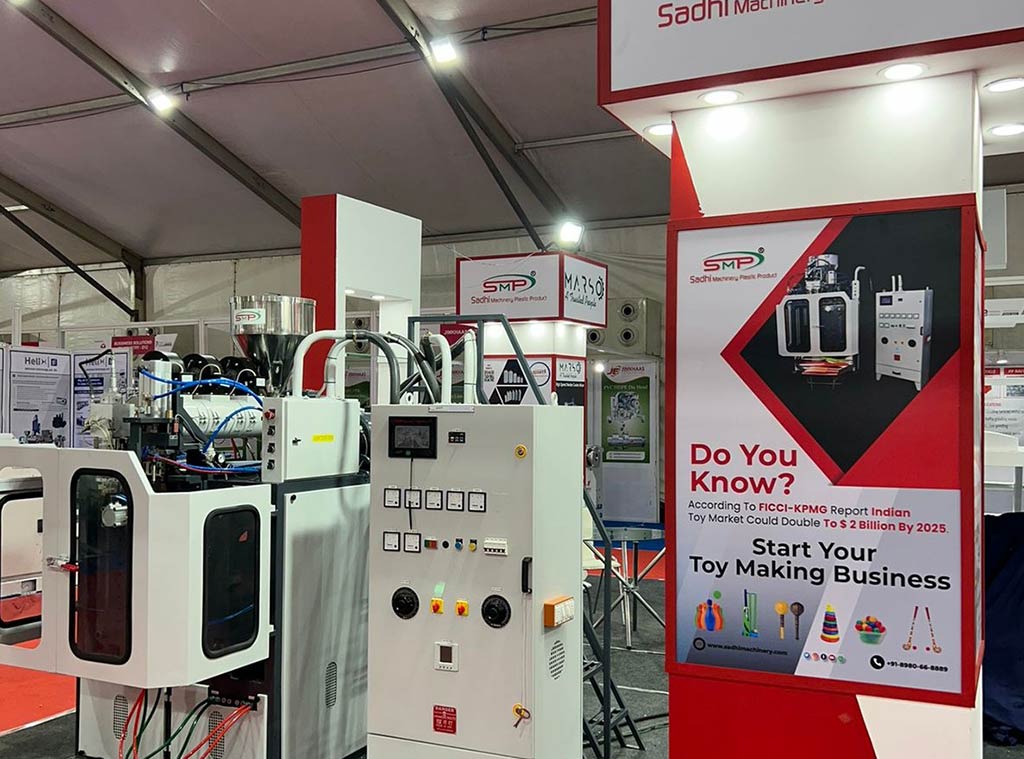

The government wants to promote the Toys business in order to manufacture as well as boost the product’s sales in India under the Made in India campaign, due to this, the toy business is constantly being encouraging.

According to the “National Investment Promotion & Facilitation Agency”, the toy industry market in India is estimating around $ 1.5 billion.

In August 2020, Prime Minister Narendra Modi also urged young businessmen to focus on innovation in the toy sector as the Indian toy market has huge potential.

The First Step Is Market Research.

Before starting the toys making business, it is important to do market research.

it is important to collect as much information as possible about this business so that you get the knowledge that what kind of toys are in demand in the market.

In order to get the information, you can go to the market and have to find out an experienced shop owner and makes an inquiry about which toy contains higher sales in the market? And you can also take a demo of the toy from that shop owner and you can make your own unique product by researching it. Also, you can make a deal with that shopkeeper to supply your product directly. So that you can get an initial boost to your product.

You can choose another way, in which you can also do online market research. For that, you can use free online sources like Google Trends, Google Consumer Survey, etc. to know what people are looking for and what is their demand?

If you have a lesser budget then you can also collect information about a particular industry, product, service from the forum website. On these websites, people give their opinion on different types of questions. Therefore, if you want, you can also take people’s opinions by putting questions on websites like Quora, Reddit.

The Second Step Is, “Innovation, Which Will Make The Business Shine.

To start a toy manufacturing business, the only investment is not required, the key of creativity is also very important, on the basis of which you will be able to be successful in the market. If you provide unique toys to the customers, then the demand for your product will also increase greatly. Having a skilled workforce, diverse range, innovation, creativity in this business can give a great boost to your business.

You can present your new toy to the people by making your own innovation in soft toys or plastic or battery-operated toys, which will increase your toys sales.

The 21st century is the era of science and technology, so you can also invent robotic toys by doing research, such robotic toys teach children about science and technology in the game. Keeping this in mind, you can invent your own sensor-based toy.

Raw Materials Selection

You will need raw materials to make toys and you can buy these raw material according to your need at low prices from wholesale. The main component used in toys is plastic, usually, raw materials such as polyethylene, polypropylene, nylon granules, polystyrene, and polycarbonate are used in toy manufacturing. In this also you can bring innovation as you can use some chemical in raw material to give softer and better color to your toys.

In order to improve your business, you can buy raw materials at a cheap price, which will also help to reduce your production cost.

The third step is to find the specific market (Find your niche) or select the toy category.

The toy manufacturing business in India is developing with a lot of opportunity and competition at the same time.

To start a toy business, you need to know what it takes to be successful in your specific market. You have to decide whether you want to manufacture soft toys, or you want to work on electronic toys?

You can also select the category according to the choice of the local people who have come up while doing the research Because initially, you will need to sell your toys in the same city or some other nearby cities.

Finding a specific market not only gives you the knowledge to meet your target customers but also their needs and preferences. keeping the Indian culture in mind, you can produce the toys of Lord Ram, Shiva, and Hanuman And you can also manufacture toys on top of local famous figures like Shaktimaan, Sakalaka Boom Boom Pencil. By making such famous toys, customers will buy more of your toys.

The fourth step is “Toys Manufacturing Machines”

The selection of machinery may differ according to the category of toys.

There are generally 3 types of machines used in the toy industry: 1 injection molding machine 2 blow molding machines and 3 sewing machines.

Today, most toys are made with blow molding machines and injection machines. With this machine, you can make toys as well as many other products.

1. Injection Molding Machine

In the plastic toy business, you can make good quality products using injection molding.

In the plastics industry, different shapes, designs, and colors can be easily given by using injection molding machines to give different molds and colors.

Product from the Injection molding machine

With an injection molding machine, you can generally manufacture hard toys. you can well-manufacture cars, toy guns, and puzzle toys.

Investment For Injection molding machine

To install an injection molding machine in your company, you will have to invest around 12 to 14 lakh rupees

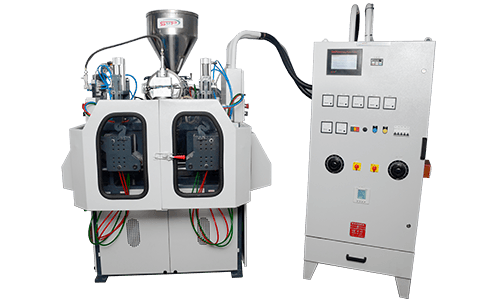

2. Blow Molding Machine

If we compare Blow Moulding Machine with Injection Moulding, the blow molding machine contains less pressure in this process. Because of this, you cannot manufacture the more rigid toys with the best quality.

Product from the Blow molding machine.

This is the reason that hollow and flexible plastic items are mostly produced by blow molding machines. With the help of a blow molding machine, you can manufacture hollow products like plastic bats, balls, plastic hammers, etc.

Investment For Blow molding machine

In order to buy a blow molding machine, you will have to invest around 15 to 16 lakhs.

3. Sewing Machine

If you want to make handmade Teddy bears or made teddy bears using semi-automatic machinery, then you can use the sewing machine.

Along with raw materials and machines, you will need secure space in which you can install machinery and make a manufacturing unit. you can use a sewing machine to make the toy by hand. Especially cloth is used in this type of toy.

Product from sewing machine

With the help of this machine, you can produce soft toys of teddy bears, birds, and animals.

Investment For sewing machine

In order to buy a sewing machine, you will have to invest about 20 thousand.

The Fifth Step is “Marketing”.

Marketing is the most important thing because marketing gives an initial boost to your start-up. With marketing, more and more people will connect with you and buy your product.

The first way for marketing is that you can sell your toys by contacting the local distributor, or you can sell your products by going to the local toy shop.

Another way is the printing section which is commonly used, in which you can publicize your product by making a banner about your product, placing a holding, so that more and more people can know this product.

You can do marketing by putting your poster on buses, rickshaws, and other public vehicles.

The third way is digital marketing, you can share about your product on social sites like Facebook, WhatsApp.

Apart from this, you can join online groups or you can also use online social media ads.

You can also meet YouTubers and talk about your products, if they like your product, then you can tell them to make a video of unboxing your product. You can also make an online review on YouTube, most important thing to remember is, if the quality and design of your product are unique, then the YouTuber will definitely unbox your product.

So, I hope these 5 steps to starting this manufacturing business will definitely prove to be beneficial for you. If you have any friends who are looking to start a new business, suggest these business ideas to them.